Products

Anti-Corrosion Coil Coating | Ozkem Coating

Anti-Corrosion Coil Coating | Coil-Type Coating

OZKEM PTY LTD. [Anti-Corrosion Coil Coating]

Australian based company formulating dip coatings for the HVAC & anti-corrosion coil coating industry since 1997.

Develops and supplies world leading technology for corrosion protection Heat exchange industry.

Next-generation Coating [Anti-Corrosion Coil Coating]

- Eco-friendly hydrophilic process

- Non-toxic

- It has 6 to 8 micron thickness, which causes no effect on heat exchange.

- Super hydrophobic to improve corrosion resistance, efficiency, and airflow by water release

- It has an antibacterial additive to inhibit bacteria or fungi that breed in coils.

- Applicable to all metal including pins, and tubes to stop corrosion

Benefits

- Life lasts more than 10 years with anti-corrosion coil coating function

- Improves product efficiency

- Reduces cleaning, service and maintenance costs

-

For low food temperatures,

- Reduces power consumption by extending the sacrificial cycle

- Functions antibacterial protection against contaminants

- Increases resistance to food products

Quality Reliability

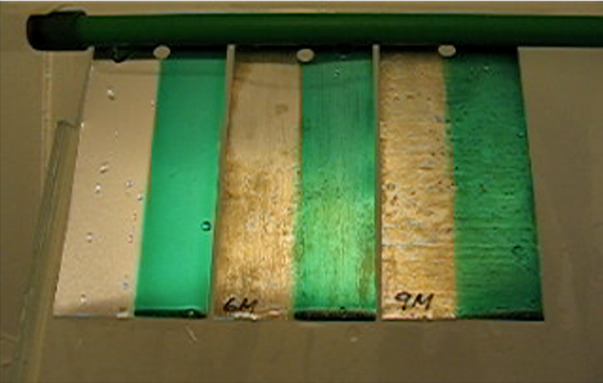

| ASTM B117 | Neutral Salt Spray | + 10,000hr |

|---|---|---|

| ASTM G85 A5 | Acidifide Salt Spray | + 2,000hr |

| ASTM G87 | Moist So2 | + 50cycles |

| ASTM D4798 | UV stavilyty | +1,000hr |

| ASTM G21 | Anti Bacterial | PASS |

| ASTM G22 | Anti Mould | PASS |

| MIL-STD-810 | ust and Mould | PASS |

Coating Method [Anti-Corrosion Coil Coating]

- Anti-corrosion coil coating when fabrication

- Applicable to new products or on-site installations

Super Hydrophobic & Anti-Corrosion Coil Coating [Microphobic Property]

If the water is discharged well by microphobic property, the efficiency of heat exchange can be maintained, and the airflow resistance can be reduced, allowing the power consumption of fans to be maintained as in the early stages of installation and maintaining the method effect for a longer period of time.