Products

Coils

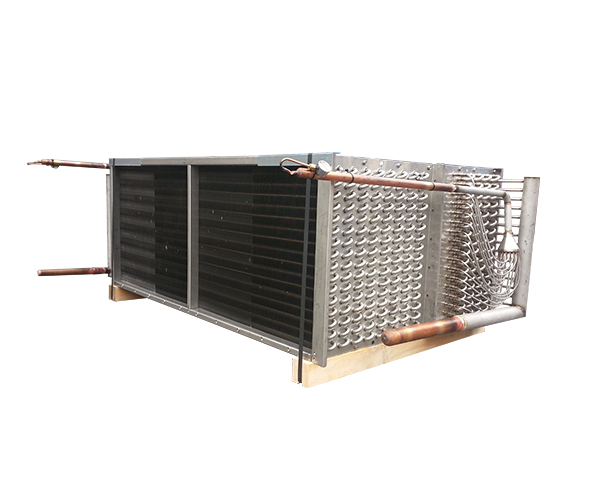

STS coil

Quote inquiry

How to produce CROSS FIN TUBE heat exchanger

The tube material of STS FIN TUBE heat exchanger manufactured by Joongwon Refrigeration & Heating can be selected from STS 304, STS316L, and it has a diameter of12.70M/M and a thickness of 0.7M/M. Heater and distributors, branches, U band, and capillaries are also made of STAINLESS STEEL. The efficiency of STS CROSS FIN TUBE is about 50% of a copper tube - aluminum FIN coil.

Pressure-proof test pressure and airtightness test pressure of CROSS FIN TUBE Heat Exchanger

| D.X COIL, EVA/COIL | HOT/COLD WATER COIL, STEAM COIL |

CONDENSER COIL |

|---|---|---|

| Pressure-proof test : 20Kg/㎠ Airtightness test : 15kg/㎠ |

Pressure-proof test : 20Kg/㎠ Airtightness test : 15kg/㎠ |

Pressure-proof test : 33Kg/㎠ Airtightness test : 25kg/㎠ |

Total heat transfer area of the coil

A (㎡) = Number of row x number of step x effective length x Selected value as follows (TA)

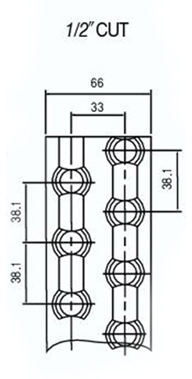

Standard FIN specification

TRANSFER AREA (㎡ / m)

| PIPE PITCH | TUBE \ FP | 2.1 | 2.5 | 3 | 3.2 | 4.2 | 4.5 | 5.5 | 6 | 6.5 | 8 | 8.5 | 10 | 12 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 33 x 38.1 | 1/2" | 1.1453 | 0.9689 | 0.8146 | 0.7663 | 0.5964 | 0.5607 | 0.4665 | 0.4312 | 0.4013 | 0.3341 | 0.3169 | 0.2763 | 0.2378 | 0.1991 |

Areas that utilize the excellent corrosion resistance of STS Coil

1. Heat recovery industry

- Use of exhaust heat (substitute carbon steel pipe for pressure piping sensitive to low-temperature corrosion)

- Industries where white lead is a problem

- The miniaturized heat recovery system of high efficiency in micro-turbine facility system

2. Industry related to edibility

- Heat exchanger required cleaning used in HACCP facility